Recycle PET Processing

PET Processors, L.L.C. (PPLLC) has been a leader in recycling PET since 1987.

PPLLC has equipment that is used to convert recycled PET flake into pellets. PPLLC’s capabilities include drying, extruding, and underwater pelletizing flake to

provide a pellet feedstock for further processing. Feedstocks are also provided to PPLLC from other

sources either post-consumer or post-industrial, typically in the

form of pellets. Either source of pellets can be introduced into

Rotary Vacuum Dryers to crystallize or increase the molecular weight

by solid state polymerizing. Complete material handling systems are

in place to provide the highest quality polymer to film, strapping,

container, and engineering plastic or other applications.

In the post-consumer area, PPLLC buys recycle PET flake

that is free of other polymer types. In the post-industrial

area, PPLLC processes clean, ground bottles or preforms, or

contaminant-free film scrap. In either case, PPLLC employs

heat under vacuum to dry flakes and remove residual

impurities.

Recycle PET Upgrading by Pelletizing & Solid State Polymerization

Processing Systems

- Current capacity 50,000,000 lbs/year

- Silo storage exceeding 700,000 lbs.

- 4.5 inch single-screw extrusion systems

- 6.0 inch single-screw extrusion systems

- Underwater pelletizing systems

- Rotary vacuum dryers to 500 cubic feet

- Fluid bed crystallizer system

- Batch blending and weighing systems

- Pneumatic transfer systems with dust removal

Testing & Specifications

- IV monitoring and control

- Color analysis

- % dust/fines

Pellet size

- % crystallized

Material Handling

- Material receiving in boxes, bulk truck, railcars and Supersacks

- Product classification of dust, fragments and oversized

- Packaging and shipping in boxes, bulk cars and railcars

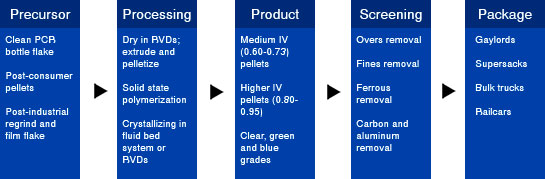

- Recycle PET Polymer Process Flow Precursor

Recycle PET Polymer Process Flow

PPLLC is a leading

thermoplastic solutions provider

PPLLC provides recycling solutions for post consumer and post industrial

resins, including PET. Single screw extrusion technology is used to melt,

process, and filter recycled flake into pellets. PPLLC's capabilities

include drying, extruding, and underwater pelletizing flake to provide a

pellet feedstock for further processing. PPLLC routinely increases the IV

of recycled polyesters and nylons for specialty applications.