Solid State Polymerization

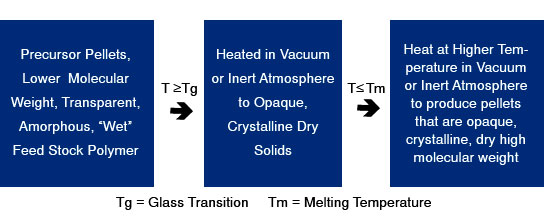

Solid State Polymerization (SSP) is a process in which the

polymer chain lengths are increased by heat in the absence of oxygen

and water, by means of either vacuum or purging with an inert gas to

drive off the by-products of reactions. The reaction is driven by

temperature, pressure, and the diffusion of by-products from the

interior of the pellet to the surface. SSP is an important step

frequently used after melt-polymerization for the purpose of

enhancing the mechanical and rheological properties of polymers

before injection blow molding or extruding. The SSP technique is

widely applied in industrial manufacture of bottle-grade PET, films,

and superior industrial fibers.

How the Process Works

- PPLLC receives PET, polyesters or other condensation polymers

made by melt polymerization

- PPLLC transfers the pellets to a Rotary

Vacuum Dryer (RVD)

- Generally, the vacuum pump removes air, water and

by-products of the SSP; alternatively, nitrogen purging is used

- The

temperature/time profile is controlled with a microprocessor

- Initial

heating at a temperature above Tg cold crystallizes amorphous

pellets to prevent sticking and fusion of pellets

- Heating is

continued to dry the ”wet” pellets

- Heating is continued to a

predetermined temperature below the melting temperature of the

polymer

- Solid state polymerization is done at a high temperature and

low vacuum (or alternatively at zero oxygen level with nitrogen

purging) to achieve the desired high molecular weight of the polymer

- The SSP progress is followed by periodically taking samples with

custom designed samplers

- The melt viscosity at a specific

temperature of that sample is determined within several minutes

- The

Intrinsic Viscosity is obtained from the Correlation Chart/Curve

established from melt viscosity data and Intrinsic Viscosity

obtained from solution viscosity at ambient temperatures for PET homopolymers

- The final product viscosity is as specified by the

customer

- A major benefit of solid state polymerization is obtaining

a desired high molecular weight polymer of uniform and consistent

Intrinsic Viscosity

- Other major benefits include the reduction of

undesirable side reactions and the levels of by-products

- For PET,

the SSP by-products are ethylene glycol and acetaldehyde

- When the

desired molecular weight is achieved, the product pellets are cooled

and transferred to storage tanks

- The product pellets are classified,

packaged and shipped according to customer requirements

PPLLC is a leading

thermoplastic solutions provider

PPLLC provides recycling solutions for post consumer and post industrial

resins, including PET. Single screw extrusion technology is used to melt,

process, and filter recycled flake into pellets. PPLLC's capabilities

include drying, extruding, and underwater pelletizing flake to provide a

pellet feedstock for further processing. PPLLC routinely increases the IV

of recycled polyesters and nylons for specialty applications.